Máquina de Tubo Espiral con Perforación

- Resumen

- Productos relacionados

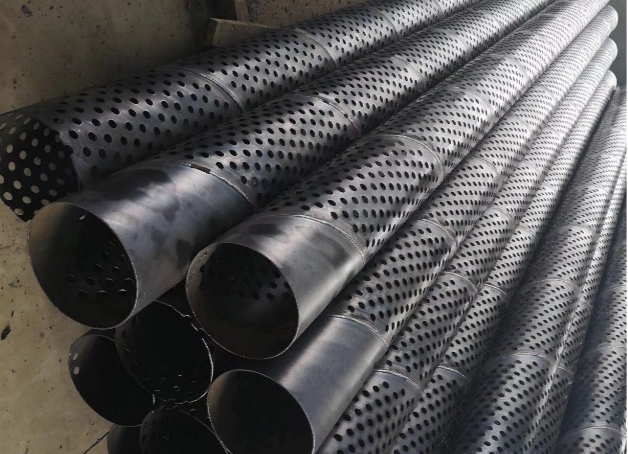

Introducción del producto

El equipo de tubería espiral soldada con perforación es un tipo de equipo especialmente utilizado para la producción de tubos espirales soldados con agujeros. Este equipo no solo completa la formación y soldadura de los tubos espirales durante el proceso de fabricación, sino que también perfora los tubos. Los tubos espirales soldados perforados se utilizan ampliamente en drenaje, ventilación, filtración de agua y protección ambiental, siendo especialmente adecuados para sistemas de tuberías que requieren funciones de ventilación, drenaje o filtrado.

El tubo filtro incluye principalmente dos tipos: agujeros redondos y puentes de agujeros. Al cambiar el diseño del molde de la prensa de perforación, se pueden cumplir las necesidades de producción de tubos filtro con diferentes tipos de agujeros.

SOLICITUD

• Sistema de drenaje: se utiliza para tuberías de drenaje subterráneo y zanjas de drenaje, lo que permite drenar el agua de manera efectiva.

• Sistemas de ventilación: como conductos de ventilación y sistemas de filtración de aire para proporcionar una buena circulación de aire.

• Sistema de filtración de agua: utilizado para dispositivos de filtración en plantas de tratamiento de agua para evitar que impurezas entren al sistema de tuberías.

• Instalaciones de protección ambiental: como tubos de escape y sistemas de tratamiento de aguas residuales, utilizando orificios para la ventilación y filtración.

Vide

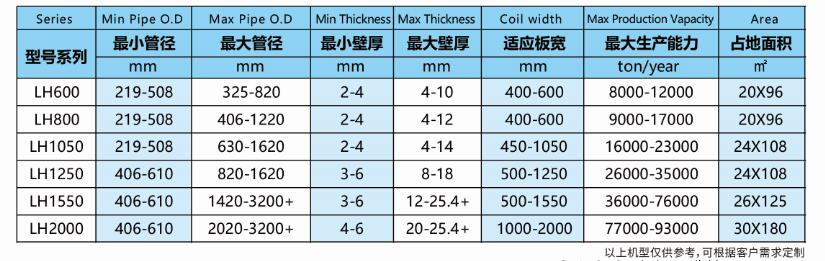

Especificaciones y modelos

Especificaciones del producto de varios modelos, altamente personalizables. Desde diseño, fabricación, ensamblaje, transporte hasta instalación, puesta en marcha, soluciones integrales de servicio postventa.

Nuestras ventajas

La máquina de fabricación de tubos en espiral es un equipo maduro con características técnicas muy competitivas en Huaye. Las especificaciones de los productos van desde Φ25mm hasta 4000 Φmm, y se dividen en máquinas estándar y máquinas personalizadas especiales.

Muchos primeros lugares nacionales y avances tecnológicos demuestran plenamente las fuertes ventajas tecnológicas de Huaye y sus capacidades de investigación y desarrollo de muchas tecnologías de vanguardia.

• El primer conjunto nacional (el segundo en el mundo) de tubos de acero soldados en espiral de aleación de aluminio-magnesio (método de soldadura de pequeño agujero) Φ200-914.

• La línea de producción de tubos de acero soldados en espiral más pequeña del país Φ25-114 para tubos de acero inoxidable.

• El primer proyecto de exportación de China de un conjunto completo de equipos de tubería soldada en espiral Φ508-1800 (estándar API).

• Un usuario nacional que produce en masa 9 conjuntos de máquinas de tubos soldados en espiral (entrega completa en cuatro meses).

producción personalizada

• Máquina de Tubos en Espiral según el Estándar API

• Máquina de Tubos en Espiral de Acero Inoxidable

• Máquina de Tubos en Espiral con Perforación

• Máquina de Tubos en Espiral de Gran Diámetro Exterior y Pared Delgada

• Máquina de Tubos en Espiral de Movimiento Oscilante Trasero

• Máquina de Tubos en Espiral para Tambores de Acero

• Máquina de Tubos Espirales de Aluminio

• Máquina de Tubos Espirales con Pared Reforzada

Huaye Con Los Clientes

Con tecnología avanzada y un excelente artesanía, hemos creado con éxito el equipo de tubería espiral soldada líder en la industria para proporcionar soluciones eficientes y estables a los clientes.

Envío

Aunque el equipo de tubería soldada tiene un gran volumen y peso, es básicamente modular. Haremos todo lo posible por diseñar cada módulo en un contenedor estándar.

Pero siempre hay algunas piezas especiales, que independientemente de cómo se cambie el diseño, exceden el tamaño del contenedor. En este caso, usaremos contenedores marcos o contenedores abiertos.

Si hay demasiadas piezas sobredimensionadas o excesivamente pesadas, también elegiremos buques graneleros para el envío.

Soporte de servicio

Taiyuan Huaye Heavy Industry Co., Ltd. puede proporcionarte un plan completo de equipos personalizados y ofrecer soporte técnico profesional, incluyendo diseño, fabricación, ensamblaje, transporte, instalación, puesta en marcha, capacitación y servicio postventa integral.

Elige Nuestra Empresa

1. Con 30 años de experiencia en I+D y fabricación, el diseño del producto, el proceso de producción y la tecnología se optimizan y actualizan constantemente;

2. Contando con una fábrica propia a gran escala, controlamos completamente cada eslabón de la producción. Estamos encantados de recibir tu visita en cualquier momento;

3. Amplia cartera de casos nacionales e internacionales, excelente reputación en el mercado, entrega de proyectos a tiempo y calidad confiable.