Déposeur de tubes——Système de convoyage tubulaire

- Aperçu

- Produits connexes

-

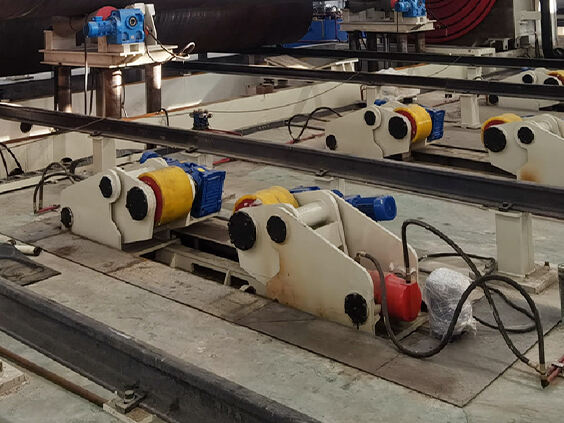

Rotateur de levage de tube

Il est utilisé pour soulever et faire pivoter le tube d'acier. Il est généralement utilisé pour le soudage de réparation des tubes soudés, l'inspection manuelle, etc.

-

Éjecteurs

Il sert à retourner le tube d'acier. Généralement, il retourne les tubes d'acier depuis le convoyeur ou les rouleaux de support vers le rack.

-

Voiture de livraison de tubes

Il est utilisé pour transporter le tuyau en acier horizontalement, il peut remplacer l'éjecteur de tube pour transférer des tubes entre le rack et le convoyeur.

-

Station de réparation de soudure

Il est utilisé pour la réparation des soudures défectueuses des tubes en acier. Inclut un rotateur de tube, un récepteur d'éjecteur de tube (ou un rotateur de tube relevable), (bras de soudage), machine à souder de réparation.

-

Convoyeur entraîné

Il est utilisé pour transporter le tuyau en acier longitudinalement.

-

Convoyeur libre

Il est utilisé pour transporter le tuyau en acier longitudinalement.

-

Rotateur de tube

Il est utilisé pour faire pivoter le tuyau en acier. Généralement utilisé pour la réparation des soudures de tubes soudés, les inspections manuelles, etc. Habituellement utilisé en combinaison avec un récepteur d'éjecteur de tube.

-

Chariot de livraison de tubes oscillant

Il est utilisé pour changer la direction de transport du tuyau en acier de 90°.

-

Machine à enlèvement de scories

Il est utilisé pour vider les résidus à l'intérieur du tuyau en acier.

-

Déposeur de tubes

Il est utilisé pour poser doucement le tuyau en acier sur le rack ou à l'étape suivante de production.

Introduction du produit

Le Pipe Dropper sert à faire tomber doucement le tuyau en acier sur le support ou à l'étape suivante de production.

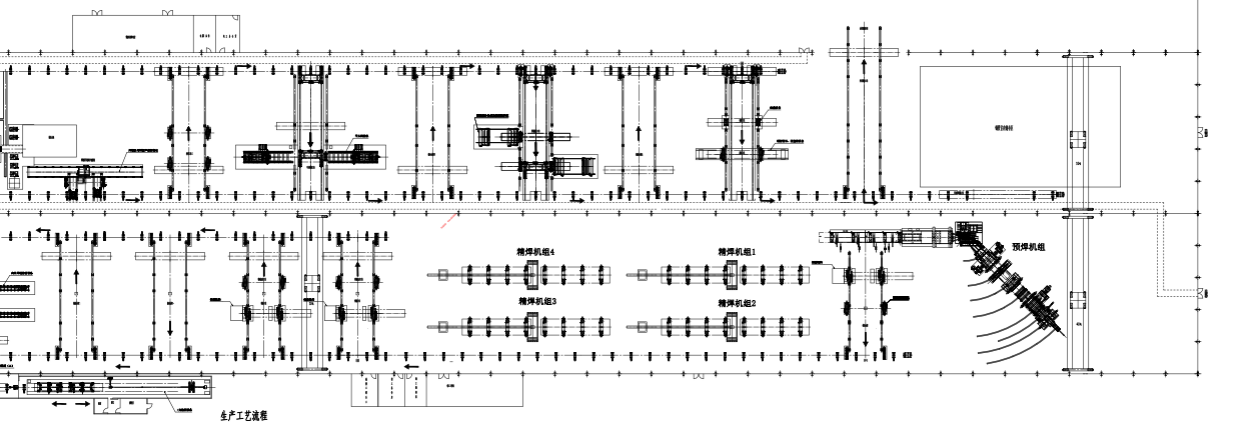

Le Système de Transport de Tuyaux fait référence à la série d'équipements après que le tuyau quitte l'équipement de production. Dans un cas de production, la Section de Finition désigne généralement le système de transfert de tuyaux. Le système inclut des convoyeurs, des supports, des éjecteurs, des rouleaux rotatifs, des chariots de livraison de tuyaux et d'autres équipements simples pour le traitement des tuyaux, tels que les machines de déshuillement, les stations de réparation de soudure, etc.

En fonction de l'état du hangar d'usine du client, les ingénieurs expérimentés de HUAYE fournissent une disposition globale et une solution de transfert de tuyauterie les plus efficaces. De plus, HUAYE propose une offre clé en main pour tout l'équipement lié à la section de finition, offrant ainsi aux clients le plus grand confort et un soutien à la production.

Comment obtenir la disposition globale du processus de production ?

● Déterminer les équipements principaux requis par l'usine.

● Déterminer la taille de l'usine ou la taille du site.

● Fournir ou confirmer le plan de l'atelier de l'usine.

● HUAYE concevra la disposition de l'atelier en fonction des équipements requis et du plan de l'atelier confirmé.

Équipements principaux de la section de finition

Huaye avec les clients

Avec une technologie avancée et un savoir-faire exquis, nous avons réussi à créer l'équipement de tube soudé en spirale de pointe de l'industrie pour offrir aux clients des solutions efficaces et stables.

Expédition

Bien que l'équipement de tube soudé ait un grand volume et un poids importants, il est en grande partie modulaire. Nous ferons de notre mieux pour concevoir chaque module selon les dimensions d'un conteneur standard.

Mais il y a toujours certaines pièces spéciales, qui dépassent la taille du conteneur, quel que soit le changement de conception. À ce moment-là, nous utiliserons des conteneurs cadre ou des conteneurs à toit ouvert.

Si le nombre de pièces surdimensionnées ou trop lourdes est trop important, nous choisirons également des navires de transport en vrac pour l'expédition.

Assistance technique

Taiyuan Huaye Heavy Industry Co., Ltd. peut vous fournir un plan d'équipements entièrement personnalisé et offrir un soutien technique professionnel, y compris la conception, la fabrication, l'assemblage, le transport, l'installation, l'essai, la formation et des services après-vente clés en main.

Choisissez notre entreprise

1. Avec 30 ans d'expérience en R&D et en fabrication, la conception des produits, les processus de production et les technologies sont constamment optimisés et mis à jour ;

2. Avec une usine de grande échelle appartenant à l'entreprise, nous maîtrisons parfaitement chaque étape de la production. Vous êtes les bienvenus pour visiter notre usine à tout moment ;

3. Une riche expérience dans des cas nationaux et internationaux, une excellente réputation sur le marché, une livraison de projets à l'heure et une qualité fiable.