Машина для производства алюминиевой спиральной трубы

- Обзор

- Связанные продукты

Введение в продукт

Алюминиевая спирально-сварная трубная линия — это оборудование,专门 предназначенное для производства алюминиевых спирально-сварных труб. Благодаря преимуществам алюминия, таким как легкость, коррозионная стойкость и хорошая теплопроводность, алюминиевые спирально-сварные трубы широко применяются в системах вентиляции, кондиционирования, отвода выхлопных газов, химических трубопроводах и других областях. В сравнении со стальными спирально-сварными трубами, сварка и формование алюминия имеют свои особенности, поэтому у алюминиевой спирально-сварной трубной установки есть специфические требования к проектированию и технологии.

Основные преимущества

• Высокоточное формование: Учитывая особенности алюминия, формующее оборудование имеет высокоточную конструкцию, которая гарантирует, что размеры и форма трубы соответствуют требованиям.

• Качественная сварка: Сварочная система специально разработана для алюминия, обеспечивая стабильные параметры сварки и эффективную защиту, чтобы гарантировать качество шва.

• Автоматическое управление: Оборудование обычно комплектуется современной системой автоматического управления, что снижает ручное вмешательство, повышает производительность и качество продукции.

• Защитные меры: Для предотвращения загрязнения или повреждения алюминия во время обработки, оборудование оснащено защитными мерами в ключевых частях, такими как антицарапинная обработка и защита от окисления.

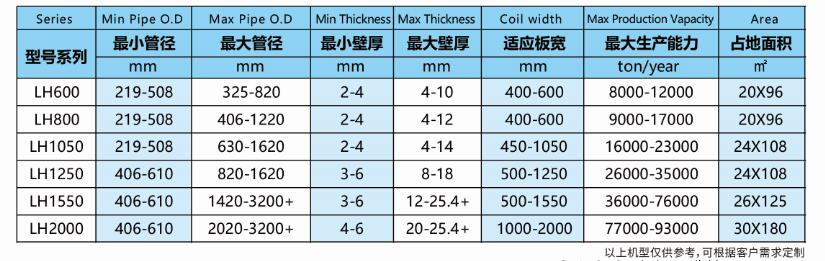

Технические характеристики и модели

Технические характеристики продукции различных моделей, высокая степень настройки. От проектирования, производства, сборки, транспортировки до установки, пуско-наладочных работ, послепродажного обслуживания — комплексные интегрированные решения.

Наши преимущества

Спиральная трубная мельница — это зрелое оборудование с очень конкурентоспособными和技术ическими характеристиками в Хуайе. Диапазон размеров продукции составляет от Φ25 мм до 4000 Φмм, и они делятся на стандартные машины и специальные заказные машины.

Множество внутренних первых разработок и достижений полностью демонстрируют сильные технологические преимущества Хуайе и способности к исследованию и разработке многих передовых технологий.

• Первая в Китае (вторая в мире) линия по производству спиральношовных труб из алюминиево-магниевых сплавов (метод малых сварных отверстий) Φ200-914.

• Самая маленькая в Китае линия производства спиральношовных труб из нержавеющей стали Φ25-114.

• Первый проект по экспорту полного комплекта оборудования для производства спиральношовных труб в Китае, диаметр Φ508-1800 (стандарт API)

• Массовое производство 9 установок для спиральношовных труб для внутреннего потребителя (полная поставка в течение четырех месяцев).

индивидуальное производство

• Машина для производства спиральношовных труб стандарта API

• Машина для производства спиральношовных труб из нержавеющей стали

• Машина для производства пробивных спиральношовных труб

• Машина для производства спиральношовных труб большого диаметра с тонкой стенкой

• Машина для производства спиральношовных труб с задним маятниковым механизмом

• Машина для производства спиральношовных труб для стальных барабанов

• Машина для производства спиральношовных труб из алюминия

• Машина для производства усиленных спиральношовных труб

Huaye Вместе с клиентами

Используя передовые технологии и тонкое мастерство, мы успешно создали ведущее оборудование для производства спиральношовных труб в отрасли, чтобы предоставить клиентам эффективные и надежные решения.

Доставка

Несмотря на то что само оборудование для сварки труб имеет большой объем и вес, оно в основном модульное. Мы постараемся спроектировать каждый модуль так, чтобы он помещался в стандартный контейнер.

Однако всегда бывают некоторые специальные детали, которые превышают габариты контейнера, как бы мы ни меняли их конструкцию. В этом случае мы будем использовать фрейтовые или открытые контейнеры.

Если слишком много перегруженных или негабаритных частей, мы также можем выбрать доставку с помощью судов-рассох.

Служба поддержки

Компания Taiyuan Huaye Heavy Industry Co., Ltd. может предложить вам полный комплекс индивидуальных решений и профессиональную техническую поддержку, включая проектирование, производство, сборку, транспортировку, монтаж, пусконаладку, обучение и послепродажное обслуживание под ключ.

Выберите нашу компанию

1. При 30 годах опыта в области НИОКР и производства, проектирование продукции, производственный процесс и технологии постоянно совершенствуются и обновляются;

2. При наличии крупного собственного завода мы полностью контролируем каждый этап производства. Приглашаем посетить наш завод в любое время;

3. Богатый опыт реализации проектов как на внутреннем, так и на международном уровне, отличная рыночная репутация, своевременная сдача проектов и надежное качество.